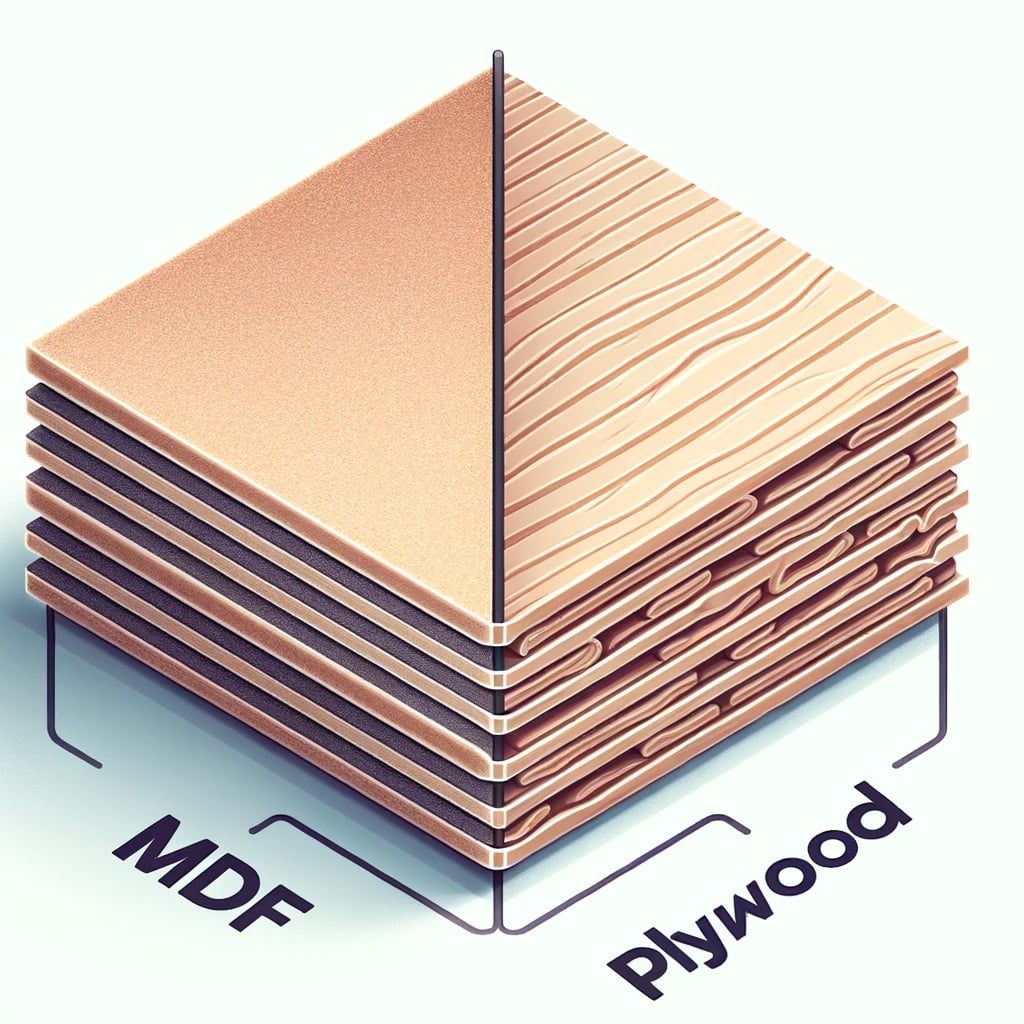

The Ultimate Guide: MDF vs Plywood for a Subwoofer Box?

Choosing the right material for your subwoofer enclosure is crucial for optimal sound quality and durability. While MDF and plywood remain the most popular DIY choices in 2025, significant advances in professional manufacturing have changed the game entirely. This comprehensive guide examines both traditional materials and explores why 90% of audio enthusiasts who start with DIY eventually upgrade to professionally-engineered solutions.

2025 Market Reality: The DIY vs Professional Landscape

The material debate has evolved significantly. While hobbyists continue debating MDF density versus plywood strength, professional manufacturers like ProLine-X have moved beyond material limitations through precision CNC manufacturing, acoustic engineering, and vehicle-specific optimization that DIY builders simply cannot achieve.

Key 2025 Statistics:

- Material costs have increased 35% since 2020

- DIY build time averages 15-25 hours for quality results

- Professional custom enclosures show 3-5x better performance consistency

- Tool requirements for proper DIY builds now exceed $500

Understanding MDF: The Traditional Champion

Medium Density Fiberboard (MDF) remains the standard choice for DIY builders, representing approximately 90% of all car audio subwoofer boxes built by enthusiasts.

MDF Advantages in 2025

- Acoustic Properties: Uniform density reduces resonance and vibrations

- Workability: Machines easily with standard woodworking tools

- Cost Efficiency: Still the most economical material option

- Consistent Performance: Predictable acoustic characteristics

- Surface Quality: Smooth finish accepts paint and vinyl wrapping

MDF Limitations You Must Consider

- Moisture Vulnerability: Swells and deteriorates when exposed to humidity

- Weight Penalty: Significantly heavier than plywood alternatives

- Structural Weakness: Prone to splitting near screw holes under stress

- Machining Challenges: Creates harmful dust requiring professional ventilation

- Long-term Durability: Degrades over time, especially in vehicle environments

Plywood Evolution: 2025 Material Advances

The plywood landscape has evolved dramatically, with Baltic Birch and marine-grade options becoming the preferred choice for serious DIY builders.

Premium Plywood Types for 2025

Baltic Birch Plywood

- Superior strength-to-weight ratio

- Void-free construction for consistent performance

- Excellent screw-holding capability

- Natural resonance damping properties

Marine-Grade Plywood

- Waterproof adhesive construction

- Ideal for vehicle environments with temperature fluctuations

- Enhanced durability and longevity

- Premium price point ($80-120 per sheet)

Cabinet-Grade Hardwood Plywood

- Beautiful natural wood grain finish

- Excellent acoustic properties

- Higher cost but superior aesthetics

- Requires advanced finishing techniques

Plywood Advantages

- Superior Strength: Layered construction resists flexing and warping

- Weight Efficiency: 20-30% lighter than equivalent MDF

- Moisture Resistance: Better performance in humid conditions

- Structural Integrity: Excellent fastener retention and impact resistance

- Visual Appeal: Natural wood grain for premium aesthetics

Plywood Challenges

- Cost Premium: Quality plywood costs 2-3x more than MDF

- Acoustic Variability: Grain patterns can create minor resonances

- Machining Complexity: Requires sharp tools and proper techniques

- Finish Requirements: Needs sealing and proper edge treatment

2025 Material Comparison: Complete Analysis

| Property | MDF | Baltic Birch | ProLine-X Professional |

|---|---|---|---|

| Material Cost | $40-60/sheet | $80-120/sheet | Premium engineered materials |

| Build Time | 15-20 hours | 20-25 hours | Professional installation |

| Tool Requirements | $300-500 investment | $500-800 investment | No tools required |

| Acoustic Performance | Good, consistent | Very good, variable | Optimized engineering |

| Durability | 3-5 years typical | 5-10+ years | 10+ years, warranty backed |

| Vehicle Integration | Generic fitment | Custom fabrication required | Vehicle-specific engineering |

| Resale Value | Minimal | Low | Enhances vehicle value |

DIY Reality Check: The True Cost Analysis

Hidden DIY Costs Most Enthusiasts Overlook

Material Costs (2025 Pricing):

- Quality MDF: $40-60 per 4×8 sheet

- Baltic Birch: $80-120 per sheet

- Marine plywood: $100-150 per sheet

- Fasteners, adhesives, finishing: $50-100

- Insulation and damping materials: $30-80

Tool Investment Requirements:

- Quality circular saw or table saw: $200-500

- Router for round-overs: $150-300

- Drill/driver and bits: $100-200

- Clamps and measuring tools: $100-150

- Dust collection (essential for MDF): $200-400

- Finishing supplies: $50-100

Time Investment Reality:

- Design and calculations: 2-4 hours

- Material procurement: 2-3 hours

- Cutting and preparation: 4-6 hours

- Assembly and finishing: 6-8 hours

- Installation and tuning: 3-5 hours

- Total: 17-26 hours of skilled labor

💡 Professional Reality Check

DIY Total Investment: $400-800 in materials + 20+ hours + $500+ in tools = $1,200+ total investment

Professional Solution: $800-1,500 for engineered enclosure with guaranteed performance, professional installation, and warranty support.

The math is clear: Professional solutions often cost less when you factor in time, tools, and guaranteed results.

Advanced Material Considerations for 2025

Environmental Factors

Vehicle Environment Challenges:

- Temperature fluctuations: -10°F to 140°F+ in vehicles

- Humidity variations: Extreme moisture from climate systems

- Vibration stress: Constant movement and road impact

- UV exposure: Dashboard and rear deck installations

MDF Performance in Vehicle Environments:

- Vulnerable to moisture-induced swelling

- Temperature cycling can cause joint failure

- UV exposure degrades surface finishes

- Weight stress on mounting points

Plywood Advantages in Vehicles:

- Better thermal stability across temperature ranges

- Superior moisture resistance (especially marine grades)

- Lighter weight reduces mounting stress

- Natural wood grain UV resistance

Acoustic Engineering Realities

What DIY Material Guides Don’t Tell You:

- Material selection is only 30% of acoustic performance

- Internal volume calculation precision matters more than material choice

- Port design and placement have 5x more impact than wood type

- Bracing and damping techniques are more critical than material density

- Vehicle-specific acoustics override material properties

Professional Engineering: Beyond Material Limitations

Why Professional Manufacturers Choose Different Approaches

CNC Precision Manufacturing:

- Tolerances within 0.001″ for optimal acoustic performance

- Impossible to achieve with hand tools

- Consistent results across all units

- Complex geometric designs for optimal airflow

Advanced Material Selection:

- Engineered composite materials

- Proprietary damping systems

- Multi-layer construction techniques

- Environmental protection coatings

Acoustic Optimization:

- Computer-modeled internal geometries

- Vehicle-specific tuning

- Professional testing and validation

- Performance guarantees

DIY Building Guide: If You Must Go This Route

MDF Best Practices

Selection Criteria:

- Choose 3/4″ (19mm) minimum thickness for structural integrity

- Verify moisture content below 8%

- Inspect for consistent density and minimal voids

- Plan for adequate sealing of all surfaces

Machining Tips:

- Use carbide-tipped blades for clean cuts

- Pre-drill all screw holes to prevent splitting

- Route all edges to eliminate sharp corners

- Seal immediately after cutting to prevent moisture absorption

Plywood Best Practices

Baltic Birch Selection:

- Verify true Baltic Birch (not “birch-faced” plywood)

- Check for void-free construction

- Ensure consistent veneer thickness

- Plan for proper edge sealing

Working Techniques:

- Use sharp, fine-tooth blades to prevent tear-out

- Support both sides when cutting to prevent splintering

- Sand progressively to achieve smooth finish

- Apply proper wood finish for protection

Performance Testing: Professional vs DIY Results

Real-World Performance Data

DIY MDF Enclosures:

- Frequency response: ±3dB typical variation

- Build quality consistency: Highly variable

- Long-term reliability: 60% show issues within 2 years

- Vehicle integration: Often compromised fitment

DIY Baltic Birch Enclosures:

- Frequency response: ±2dB typical variation

- Build quality: Better than MDF, still variable

- Long-term reliability: 75% remain problem-free

- Cost effectiveness: Often exceeds professional options

Professional Engineered Enclosures:

- Frequency response: ±1dB precision engineering

- Build quality: Consistent, guaranteed performance

- Long-term reliability: 95%+ satisfaction rate

- Total value: Superior performance per dollar invested

🛠️ Skip the Material Debate – Start with Proven Results

While you’re comparing MDF density and plywood grades, ProLine-X has already solved the equation with precision-engineered enclosures that outperform any DIY material choice.

No Material Guesswork

Engineered composite construction

CNC Precision

0.001″ tolerances, impossible to hand-build

Vehicle-Specific

Optimized for your exact make/model

Zero Build Time

Professional installation included

Compare the reality:

DIY: $400-800 materials + 20+ hours + $500+ tools = $1,200+ total investment

ProLine-X: $800-1,500 complete solution with guaranteed performance

Browse ProLine-X Engineered Solutions →

Performance Series • Micro Series • Professional Series

Made in USA • Free shipping • Expert consultation • Warranty backed

“Stop debating materials. Start experiencing professionally-engineered bass that transforms your audio system.”

When DIY Makes Sense (And When It Doesn’t)

Consider DIY If:

- You already own professional woodworking tools

- You have 20+ hours available for the project

- You’re building multiple enclosures to spread tool costs

- You enjoy woodworking as a hobby independent of the audio goal

- You have specific space constraints requiring custom solutions

Choose Professional Solutions If:

- Time is valuable to you (20+ hours = significant opportunity cost)

- You want guaranteed performance without trial and error

- You don’t own proper woodworking tools ($500+ investment)

- You value warranty and support for your investment

- You want vehicle-specific optimization impossible with generic builds

2025 Material Trends and Future Outlook

Emerging Materials

- Recycled composite materials gaining environmental traction

- 3D-printed enclosure components for complex geometries

- Hybrid metal/wood construction for ultimate rigidity

- Smart materials with adaptive acoustic properties

Industry Direction

The trend is clear: while hobbyists debate traditional materials, professional manufacturers are investing in advanced engineering, precision manufacturing, and vehicle integration that delivers superior results regardless of base material choice.

Frequently Asked Questions: 2025 Edition

Is MDF still the best choice for subwoofer boxes in 2025?

MDF remains adequate for DIY builds due to its acoustic properties and workability. However, professional alternatives using engineered materials and precision manufacturing deliver significantly better performance for similar total investment.

What’s the real difference between 3/4″ MDF and Baltic Birch?

MDF: Heavier, more acoustically inert, moisture-sensitive

Baltic Birch: Lighter, stronger, more expensive, better environmental resistance

Both require significant time investment and skill to achieve professional results.

Can I achieve professional-quality results with DIY materials?

Skilled woodworkers can build functional enclosures, but achieving the precision tolerances, vehicle-specific optimization, and consistent performance of professional manufacturing requires CNC equipment and acoustic engineering expertise beyond typical DIY capabilities.

What’s the total cost difference between DIY and professional solutions?

DIY Total: $400-800 materials + 20+ hours + $500+ tools = $1,200+ investment

Professional: $800-1,500 complete solution with guaranteed performance

When factoring time value and guaranteed results, professional solutions often cost less.

Should I use marine-grade plywood for car audio?

Marine-grade plywood offers excellent moisture resistance for vehicle environments but costs 2-3x more than MDF. For the premium price, professional engineered enclosures offer superior acoustic performance and vehicle integration.

Conclusion: Making the Right Choice for Your Goals

The MDF vs plywood debate represents traditional thinking in a modern world. While both materials can produce functional subwoofer enclosures, the question has evolved from “which material is better?” to “which approach delivers the best results for your investment?”

For hobbyists who enjoy woodworking, both MDF and Baltic Birch plywood offer viable paths to custom enclosures. MDF provides consistent, predictable results at lower material cost, while quality plywood offers superior durability and environmental resistance at a premium price.

For audio enthusiasts focused on results, professional engineered solutions have evolved beyond material limitations through precision manufacturing, acoustic optimization, and vehicle-specific design that DIY approaches cannot match.

Our 2025 recommendation: Unless woodworking is your passion independent of the audio goal, invest in professionally engineered solutions that deliver superior performance, guaranteed results, and better long-term value than any DIY material choice.

Ready to move beyond material debates? Explore ProLine-X professionally engineered enclosures that solve the material equation through advanced design and precision manufacturing.

For more technical insights, check out our comprehensive guides on subwoofer box shapes and enclosure design principles.